Identifying Causes and Solutions for Oil Canning in Metal Roofing

Oil canning is a common concern in the world of metal roofing. It is essentially a moderate deformation or buckling of sheet metal, often seen on the flat surfaces of standing seam metal roofing panels. This unwanted appearance of wavy or rippled lines can detract from the overall aesthetics of your home. In this blog, we will explore the causes of oil canning and provide some possible solutions.

What is Oil Canning?

Oil canning, also known as stress wrinkling or elastic buckling, refers to the visible waviness or rippling that can occur in metal panels. It is more noticeable on flat panel products like standing seam metal roofing.

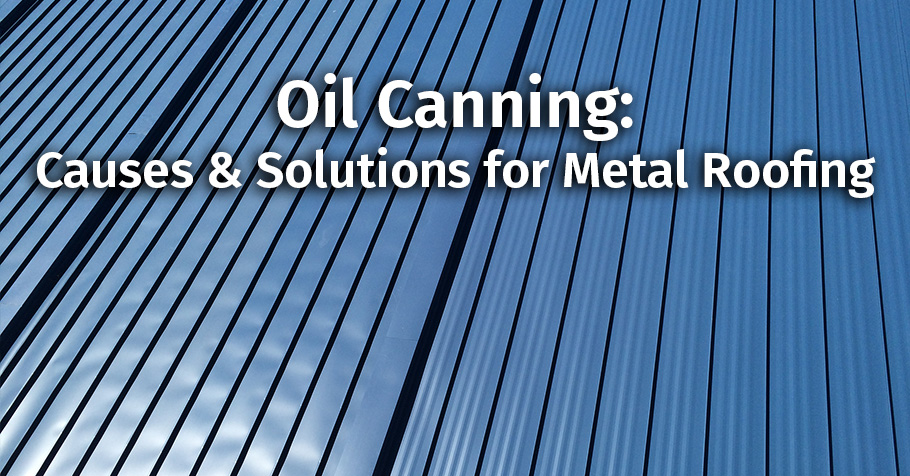

The cover image above compares two typical standing seam metal roof types. On the left, the metal panel is a typical flat pan, while the panel type on the right is striated. The difference between the two types is unmistakeable.

Sometimes, oil canning can appear more pronounced depending on the angle you’re viewing a roof or the way sunlight is reflecting from the metal surface. The rippling appearance can be quite frustrating for those seeking a seamless and blemish-free appearance.

Although oil canning is often seen as an undesirable aesthetic issue, it should be understood that it is a natural characteristic of all cold-rolled flat metal and should not be a reason for rejection. Despite the fact that many people find the appearance unappealing, it does not negatively impact the structural integrity of the metal or its ability to remain waterproof.

ASC Building Products’ Technical Services Manager mentions, “Oil canning is caused by internal stresses within thin-gauge metals. These stresses can be introduced during the production of the metal and/or the fabrication of the panels. Field installation and conditions can also greatly impact the presence of oil canning.”

Common Causes

1. Thermal Expansion and Contraction: Metal expands and contracts with temperature changes, and if the panel is not installed correctly or restrained, it can lead to stress in the panel and result in oil canning.

2. Manufacturing Imperfections: Variations in the manufacturing process, such as uneven tension in the metal or variations in the thickness, can contribute to the issues.

3. Improper Handling and Storage: Mishandling the metal panels during transportation, storage, or installation can cause distortion or dents, leading to unsightly appearances.

4. Insufficient Substrate Support: Inadequate structural support, such as uneven, warped, or weathered plywood, can cause metal panels to flex, leading to a rippling effect.

Solutions to Minimize Oil Canning:

1. Proper Installation: Following the manufacturer’s guidelines for installation is crucial to minimize the risk of an unsightly appearance. Proper fastening, spacing, and support are essential to ensure the panels are installed correctly.

2. Panel Selection: Choosing metal panels with striations or ribs can help reduce wavy or rippling appearances.

3. Adequate Substrate Support: Ensuring the framing members are properly spaced and structurally sound to help minimize flexing.

4. Regular Maintenance: Conducting routine maintenance, such as cleaning debris and inspecting for any signs of damage, can help prevent any issues from worsening.

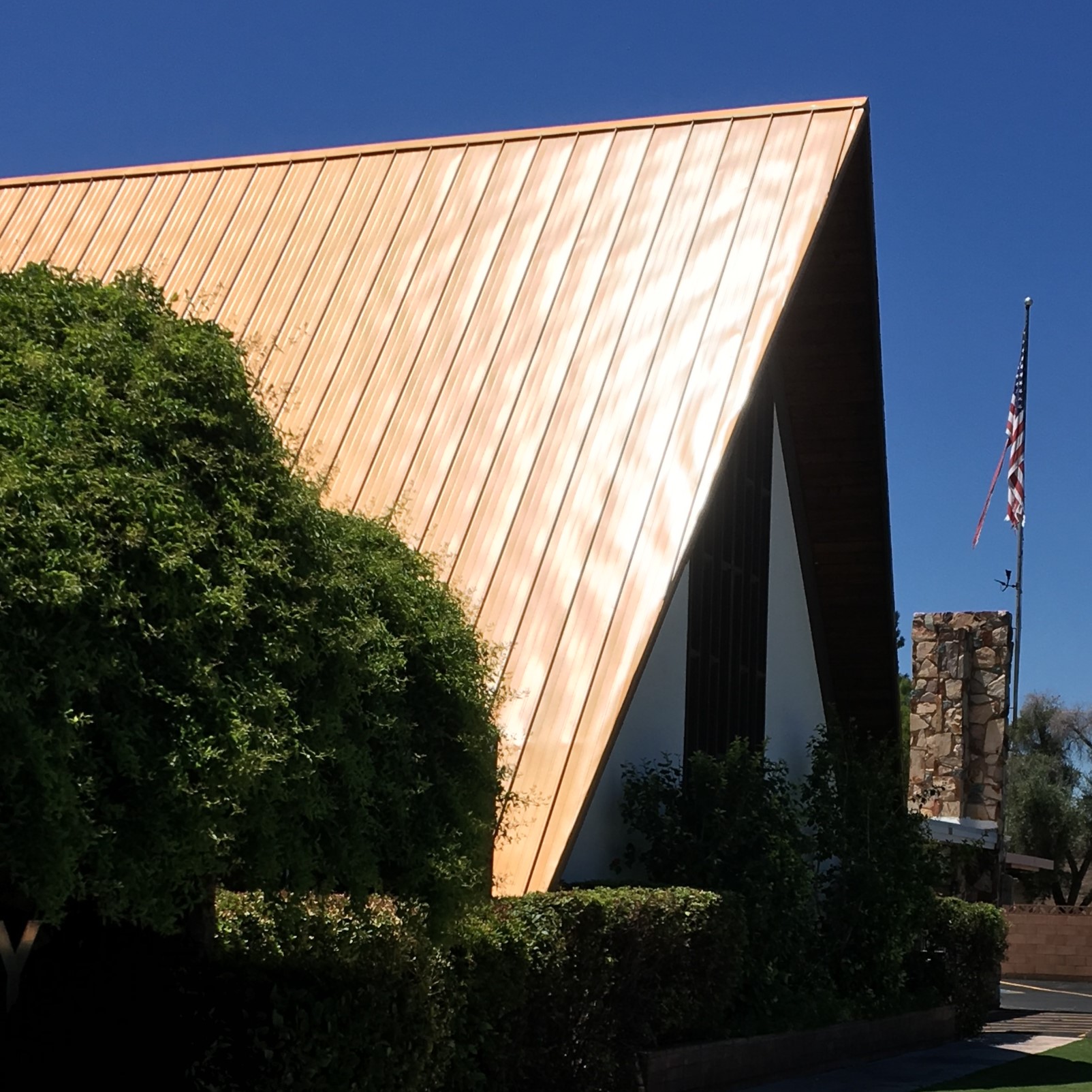

Residential projects featuring Skyline Roofing

If you’re deliberating on the ideal metal roofing panel for your home, consider these additional points.

- Ribbed or corrugated panels, like Nor-Clad® or 2 1/2″ Corrugated, generally exhibit minimal to no visible oil canning.

- Since oil canning is more visible on flat parts of a panel, opting for a narrower panel width can help reduce the issue.

- Skyline Roofing® is available in two standard variations: Striated and Ribbed. It is also available in two standard width sizes: 12″ and 16″.

Summary:

Remember, oil canning may not always be completely avoidable, especially in certain weather conditions or with extensive panel spans. However, by understanding the causes and implementing appropriate solutions, you can significantly reduce the occurrence and minimize the visible effects of oil canning on your next metal roofing project.

For more information, check out this great article from Metal Construction News. For more information on our metal roofing products that are designed to minimize the appearance of oil canning, check out our striated panel options or contact our team of experts, who will be happy to assist you.

Did you find this article helpful?