Do you have questions regarding ASC Building Products’ metal roofing and siding panels? Below is a list of the most frequently asked questions and information which will help you learn more about our products.

Frequently Asked Questions and Glossary

Frequently Asked Questions

Do hot and cold temperatures affect a steel roof?

Yes. Expansion and contraction should be taken into consideration when installing a steel roof. There are several variables involved, but one can expect a steel roof or siding panel to grow (or shrink) approximately 1/8” for every 10ft in length. A 40-foot-long panel can change length by more than ½”. If possible, allowing panels to grow and shrink with changing ambient conditions will help reduce chances of panel distortion, damage, etc.

How long will steel roofs last?

When installed and maintained properly, metal roofing can last as long as fifty years or more and still maintain its beauty, while other traditional shingle and shake roofs need replacing after an average of 10-15 years.

Will a steel roof rust?

Not for many years if proper precautions and maintenance are followed. Most ASC BP steel roof and siding panels have a ZINCALUME® coated substrate, a metallic coating combination of zinc and aluminum. A zinc-aluminum coating provides upwards of 2-3 times the corrosion protection of similarly coated zinc or galvanized coatings.

How much does an ASC Building Products steel roof weigh?

ASC BP steel roofing is a very strong, yet lightweight material compared to other roofing products. It depends on panel shape and panel gauge, but typically runs somewhere between 12oz/sq-ft to 1.5lbs/sq-ft. This is substantially lighter than asphalt shingles or clay tile that may weigh 3lbs/sq-ft to 6lbs/sq-ft respectively.

How is a steel roof good for the environment?

First steel is made from recycled material. About 25% to 30% of the steel used in an ASC Building Products metal roof is melted down from recycled steel. Unlike other roofing products, steel roofs can be recycled at the end of their useful life. Finally, steel roofs with Cool Colors can save your home up to 40% in summer cooling costs and steel roofs are highly emissive (they cool off quickly after the sun goes down) which can reduce air temperatures in urban cities. Combined, these benefits mean less dependence on energy resources and less general air pollution in your neighborhood. Steel roofing is considered a “green” product.

Why standing seam vs. exposed fastener panels?

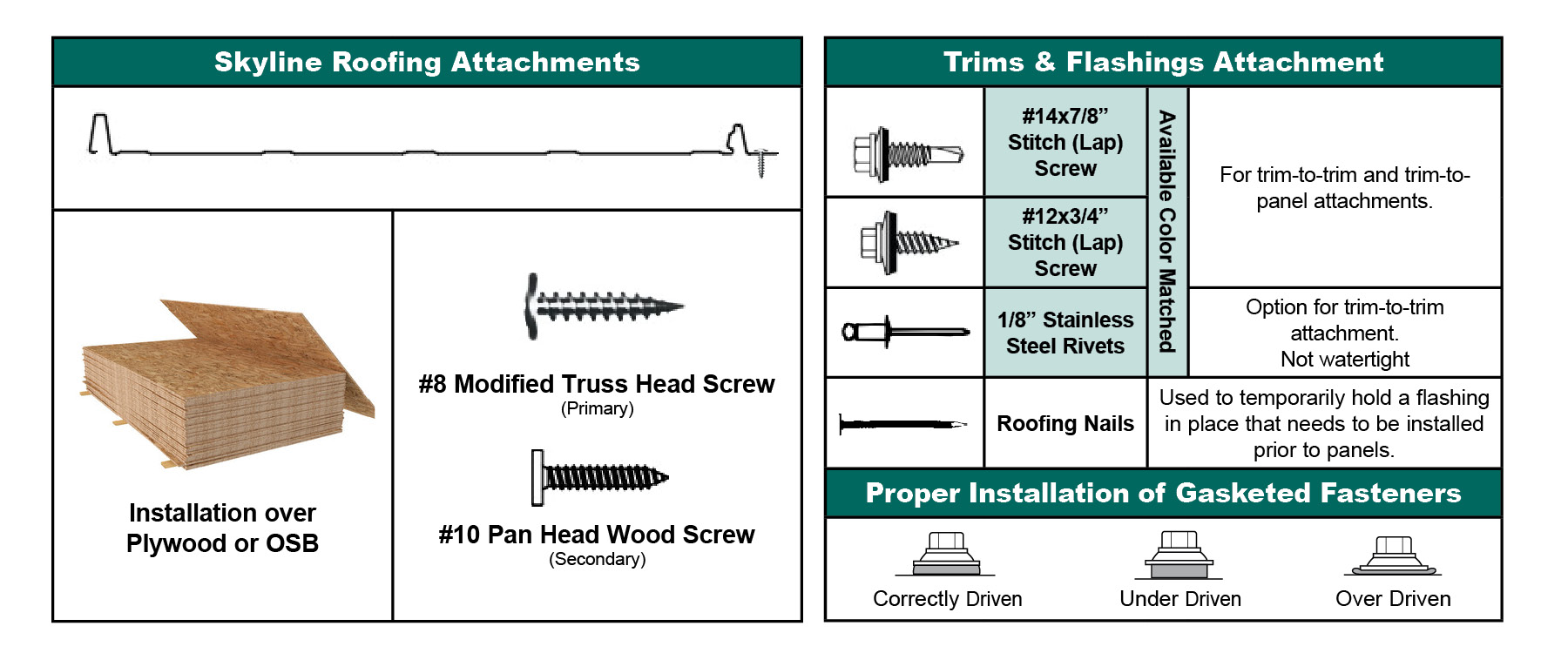

Performance and aesthetics. Standing seam panels like our Skyline Roofing and Design Span hp have hidden attachment fasteners. The hidden fasteners help maintain the very clean look of the metal roof and assist in addressing thermal expansion and contraction. In addition, hidden fasteners are less susceptible to the potential of water intrusion. See all of our concealed fastened panels here.

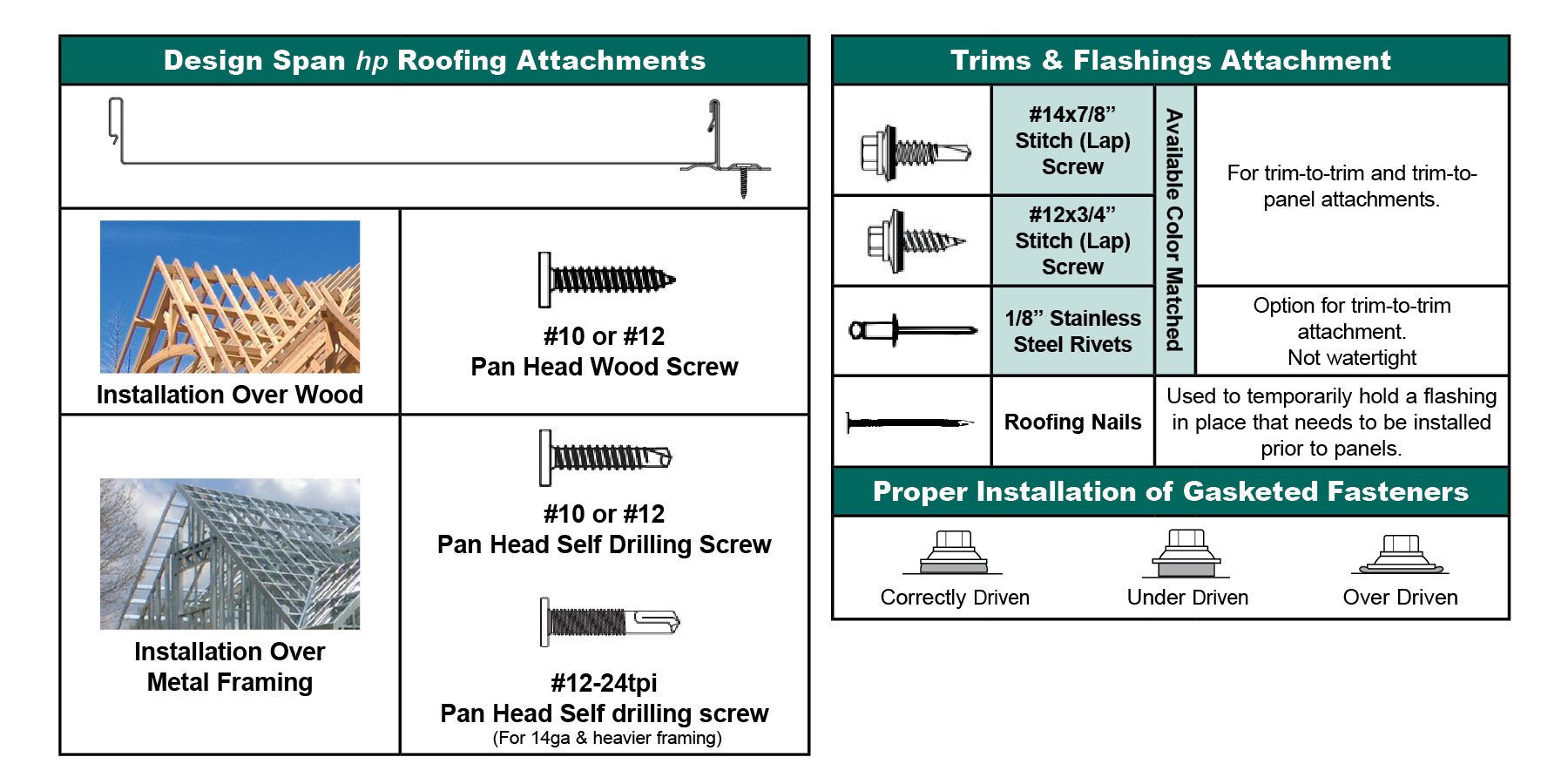

Exposed fastener panels, are great products as well. They install fast, provide an alternate look to the roof, and are generally more economical. See all our exposed fastener panels here.

Is water runoff from ASCBP metal roofing potable (drinkable)?

Metal is one of the best roofing materials for the collection of rainwater, however we take the position, it is not recommended for use in potable water applications. There has been some independent testing done which indicates that water runoff from painted metal roofs does not leach appreciable amounts of hazardous materials into the water however this does not take into account all factors – environmental, regulatory, etc.

What is the cost of a steel roof?

The cost of a metal roof will vary depending on the roofing panel width, thickness/gauge and the shape and pitch of your roof. An experienced metal roofing contractor can easily determine the right profile and gauge that will be best for your building. They will also be able to provide material and labor estimates. Check with a nearby roofing distributor or lumber yard for a qualified contractor in your area.

Is metal roofing expensive?

The cost of metal roofing is very comparable to other high-quality roofing materials. The extreme durability and longevity of metal roofing makes it a very worthwhile long-term investment. Metal roofing may be slightly more expensive in the short term, but cheaper in the long term.

How do I obtain a quote for ASCBP products?

ASC Building Products has a network of reliable metal roof and metal siding distributors, lumberyards, and home improvement merchants throughout the Western United States. Visit our Distributor Search for assistance in locating a distributor near you or you can request a quote by submitting a Product Inquiry.

Does metal roofing require any maintenance?

When properly installed and maintained, metal roofing will last many years with very little maintenance. The primary maintenance required is the occasional removal of debris that may accumulate up on the roof surface (leaves, pine needles, etc). On the ASC Building Products website, check out our Roof System Care and Maintenance technical bulletin which details good practices for cleaning and maintaining your metal roof.

What is a good way to clean metal roofing?

On the ASC BP website, check out our Roof System Care and Maintenance technical bulletin which details good practices for cleaning and maintaining your metal roof.

Is it OK to walk on a metal roof?

It is acceptable to walk on a metal roof if the entire roof assembly, including substrate, has been properly designed to withstand foot traffic and other associated building loads. Before installing a metal roof, understand what loads may be applied to the roof – wind, snow, equipment, foot traffic, etc. – and ensure the roof assembly has been appropriately designed and installed to withstand these loads. Seek the help of a design professional as required and be sure to follow applicable building codes.

What are the primary advantages of a metal roof over other roofing products (shake, tile, composition shingle, etc.)?

Each roofing material has its pros and cons. Metal roofing excels in providing excellent protection from the elements (rain, snow, hail, wind), comes in many shapes and colors, and is by far the lightest roofing material available – without compromising strength. Having a sleek metal roof that can provide many decades of continuous strength and beauty is an appeal to many potential customers. Check out our Benefits of Metal Roofing to learn more advantages.

Does metal roofing get hot like composite shingles?

In general, no. The pigments used in metal roof coatings are specifically designed to reflect the sun’s energy, as well as effectively shed any excess heat that may develop. Learn more about the cool colors we use by reading our blog, Energy Efficient Cool Colors in Today’s Metal Roofing.

What types of warranties does ASC Building Products offer?

We offer metal roof coating warranties. Please refer to our coatings and warranty information on our website or click here to view warranties. The length of warranty will depend on the product/paint system chosen. Our warranties range from 25 years to limited lifetime.

What is ZINCALUME® and ZINCALUME® Plus?

Many people are familiar with Zinc coated (galvanized) metal parts. Most of ASC Building Products’ metal roof and siding panels are furnished with a ZINCALUME® coated steel substrate. A ZINCALUME® coated substrate incorporates an aluminum alloy within the zinc coating to greatly enhance the corrosive resistance of our metal roofing products.

A ZINCALUME® Plus finish is the natural zinc-aluminum coated substrate, coated with a clear, low gloss acrylic. This coating allows ASC Building Products to produce a panel with the beauty of a bare metallic coated panel, with some of the benefits of a painted product. One of the key benefits is that the coating helps maintain a uniform finish that can be difficult to maintain with a bare metallic panel.

What are cool colors?

Cool colors reflect paints designed with infrared reflective (IR) pigments. These pigments are altered chemically and physically to reflect infrared wavelengths while still absorbing the same visible light. Compared to UV and visible light, near infrared light creates heat buildup within a structure. The purpose of these pigments is to minimizes heat buildup, reducing the cooling costs of the structure. This also means, darker colors which are typically less reflective are still able to embody reflective characteristics. However, note that a lighter ‘cool’ color will still offer superior reflective properties compared to a darker ‘cool’ color.

What is silicon modified polyester or SMP paint?

Silicon Modified Polyester (SMP), also known as Enhanced Polyester reflect a more UV resistant version of a polyester paint system commonly used in residential metal roof and wall products. SMP systems include a silicone intermediate that is reacted with the polyester to enhance exterior weatherability. SMPs are often selected for their combination of performance and economical cost underpinning their common use in residential applications. SMPs offer good exterior weatherability and improved resistance to chalk and fade compared to standard polyesters. Check out our blog, Good, Better, and Best Paint for Metal Roofing & Siding for help in deciding which paint system is best for your project.

Will the color of the metal roofing fade?

The metal roof paint coatings utilized today are significantly more resistant to paint chalking or fading compared to roofs many decades ago. ASC Building Products metal roof and siding panels are highly resistant to chalking and fading. ASC Building Products Dura Tech xl coatings are even backed by a limited lifetime warranty. See all the colors and paint systems available by checking out our Interactive Color Chart.

Does a metal roof need to be installed by a professional contractor?

While metal roofing can be installed by a homeowner, we strongly suggest the installer be thoroughly comfortable with all the elements of panel installation and any associated building code requirements, etc. Metal roofing installation can be slightly more involved than with asphalt shingles, and proper installation is key to roof integrity and a watertight assembly. A metal roof can be a lifetime investment. We always recommend working with a qualified metal roofing installer if possible.

Does an existing roof need to be removed when installing a new steel roof?

ASC Building Products steel roofs may be installed over other roofing materials however it is always recommended that the existing roofing material be removed so the roof sheathing and roof penetrations may be inspected for any damage or dry rot. In addition, the cleaner and flatter the metal roofing substrate, the better the chance of a stress-free installation. Metal roofing is a long-term investment. It’s always best to start with a good, flat, secure foundation for your roofing material.

Can the metal roofing be installed at slopes lower than those recommended by ASC Building Products?

Within ASC Building Products’ code compliance reports, installation guides, and other literature, we provide recommended minimum slopes for our roofing products. These recommended minimum slopes are defined to ensure effective rainwater removal while helping the roof panel joints stay above the water line and remain as watertight as possible.

That said, some customers do install our products below our recommended minimum slopes. Please note that this does go against our recommendations. Also be advised of any minimum slope requirements that may exist with your building codes.

Do I have to follow ASC Building Products' installation guides?

It is generally recommended to follow the installation concepts we present to best insure a good, sound, installation. We call these ‘guides’, vs. ‘manuals’ for a reason. We present our installation details to help ‘guide’ the installer to a sound, metal roof or siding installation. We understand that every project is unique, and there may be alternate ways to achieve the end goal.

What are common tools used for installing metal roofing?

Metal roofing can be installed with basic tools such as metal snips and shears, cordless drills, caulking guns, and sheet metal pliers. Sheet metal edges are sharp, and cut resistant gloves and clothing are always recommended.

Does ASC Building Products offer design or installation assistance?

ASC Building Products is first and foremost a metal roofing manufacturer. While our goal is to provide the best possible product and product data to the market, we are unable to provide project-specific design assistance. We recommend reaching out to design professionals, or qualified metal roofing suppliers and installers for specific assistance for your projects. You can also always reference our Installation Guides found in our Document Library

What substrate requirements are required for ASC Building Products metal roofing?

All ASC Building Products metal roofing products can be installed over solid substrates (plywood, OSB,..) or over closely spaced supports, like skip-sheathing. Some products may also be installed over spaced supports (rafters, purlins, etc..). Actual limitations are dependent upon project conditions, so it is advised to consult a design professional as needed. Skyline Roofing and Skyline Roofing hp are two products we recommend only installing over solid substrates.

What attachment pattern or spacing should be used to install ASC Building Products roofing products?

Our recommendation is to work with a design professional to best understand the building loads for your project. These include primarily wind and snow loads, but there may be others. Once the load requirements are defined for the metal roof or siding panels, our IAPMO-UES building code compliance report can be consulted to determine what attachment type and spacing is required for your particular project. Links to this code compliance report and associated performance tables can be found on our website.

What is the best underlayment to use with ASC Building Products metal roofing?

There are many underlayment options available today. As a starting point, ASC Building Products requires a minimum 30# felt (or equivalent synthetic) be utilized as a metal roofing underlayment. ASC Building Products recommends (and sells) a rubberized, cold-applied membrane as a higher quality protective barrier. Some underlayments are required to address particular building code requirements. A very important one is projects that are required to meet a Class ‘A’ fire resistance. A Class ‘A’ fire resistant roof assembly requires a non-combustible roofing substrate under the ASC Building Products metal roofing panel. For installations over wood decking, GAF “VersaShield Underlayment”, Firestone CLAD-GARD SA, or ¼” min G-P Gypsum DensDeck is required to obtain the Class ‘A’ fire rating. Above all, please review local codes and regulations to ensure the roof assembly is properly installed with an acceptable underlayment.

Are ASC Building Products steel roofs Class A Fire Rated?

ASC Building Products coated steel roof panels have been classified as non-combustible through ASTM A136 testing and have zero flame spread propagation as evaluated through ASTM E84. It is important to note that a ‘Class A’ fire rating is a complete roof assembly fire classification and includes the metal roofing, underlayment and substrate, all evaluated together. Since metal roofing panels are a good conductor of heat, the panels need to be installed on a non-combustible substrate for the entire roof assembly to achieve the Class A fire rating. For installations over wood decking, the addition of GAF “VersaShield Underlayment”, Firestone CLAD-GARD SA, or ¼” min G-P Gypsum DensDeck is required to obtain the Class ‘A’ fire rating. Please consult local codes and regulations to ensure your project meets any other requirements that may apply.

Does your metal roof and siding products meet the requirements of IWUIC (International Wildland-Urban Interface Code)?

Yes. Our metal roof and siding products are acceptable for use in IWUIC governed projects.

Does ASC Building Products roof and siding panels meet building code (IBC, IRC, CBC, CRC, etc) requirements?

Yes, most ASC Building Products metal roof and siding products have been stringently tested and evaluated by an independent, certified code compliance approval agency. ASC Building Products products are certified by IAPMO-UES, one of the two most prominent code approval agencies in the U.S. Our products are certified to be code compliant to International Building Code (IBC), International Residential Code (IRC), California Building Code (CBC), and California Residential Code (CRC). Many jurisdictions accept one of these code models or a variation thereof. Most competitive products have not taken these steps to ensure their products fully certified to building codes and associated standards.

Why does Skyline Roofing have exposed fasteners along the eave?

To allow Skyline Roofing to thermally expand and contract due to outside ambient temperatures, one end of the panel is ‘fixed’ to keep the panel from sliding off the roof, and the other end of the panel (under the ridge cap) is allowed to move with changing temperatures. In conditions where high snow loads occur, there may be extra fasteners at the eave to resist these downslope snow ‘drag load’ forces.

What is Drag Load?

A drag load is the force imposed upon a sloped roof panel by gravity loads, most notable is the accumulation of snow on the roof. Some roof panels are designed to freely float to accommodate roof thermal expansion/ contraction. If these roof panels are not fixed at one end of the roof panel, the panel could slide (be dragged) downslope due to the loads. Generally, this is managed by either one row of fasteners along the top edge of the roof panel (under ridge cap), or along the eave. The type and number of fasteners needed to resist drag load forces is determined by investigating the substrate material, roof slope, panel length, panel width, and geographical snow load. In heavy snow country it is recommended a design professional review drag load resistance to ensure the adequate number of drag fasteners are utilized. Note corrugated metal roofing panels are typically installed with many fasteners across the surface area of the panel and therefore can more readily accommodate drag loads.

Is condensation (sweating) a problem with metal roofing?

Like what occurs on the surface of a bathroom mirror after a hot shower, warm moist air will condense on cooler surrounding surfaces. In nearly all metal roofing applications this is not a concern. There is either a layer of an insulating material between the underside of the roofing and the moist air, or the metal roofing will be utilized in an unconditioned building like a barn where the inside and outside air is the generally the same temperature and opportunity for condensation is very minimal.

Will a steel roof make your house hot inside during the Summer?

No. Just the opposite, with ASCBP’s “Cool Colors”, homes and attics will remain cooler longer compared to homes with conventional non-cool composition shingle roofing, reducing energy costs during the hot summers months. Our DuraTech®xl paint system is formulated with special pigments that reflect rays from the sun. An ASC BP metal roof in Cool Winter White can reflect as much as 70% of the sun’s rays, keeping your home cooler during hot summer days. A study by Oakridge National Laboratory showed that a “cool” white metal roof reduced energy bills in the summer by up to 40%.

Does a steel roof make noise during a rainstorm?

This is a very common question about metal roofing. This question often stems from those who have experienced rain hitting an open, uninsulated barn or shed. If the roof is installed over Oriented Strand Board or Plywood decking, and/or over an insulated space, the sound of the rain will be essentially no different than any other roofing material.

Does metal roofing attract lightning?

Lightning attraction has more to do with building height and geography around building (ie., hilltop vs valley) vs roofing material. Because metal roofing is conductive, the relatively large metallic surface of an ASC Building Products steel roof will provide at some assistance in dissipating any lightning strike. In addition, the non-combustible metal roofing will also assist by not supporting combustion. For areas prone to lightning strikes, the use of a lightning protection system is recommended, just like they would be for any other roofing construction material.

What options exist for snow retention (snow guards or rails)?

There are several products in the market that are good for snow retention. Steel roof panels, especially standing seam roofing panels, are ideal roofing products for attaching snow retention devices. Please be advised that ASC Building Products does not recommend or promote one retention device over another. Also be aware of any impacts these devices may have on paint/coating warranties.

Are they any additional considerations for roofs in heavy snow regions?

There are several key things to consider when installing roofing in snow country. Most of these apply to all roofing materials, not just metal roofing. Inward (gravity) loads from snow can easily surpass 200lbs for every square foot of roof in some parts of the country. Ensure the entire roof structure can support these loads. Snow loads also impart drag forces on metal panels. These are downslope forces that act to pull the metal panels off the substrate. A proper amount of panel fasteners is required to ensure the panels stay on the roof. Ice damming can also be an issue. Pursuing options to avoid ice dams from occurring and using a premium rubberized underlayment like the one ASC Building Products offers will help ensure water intrusion and damage does not occur.

What is ASC Building Products metal roofing’s resistance to hail?

ASC Building Products metal roofing panels have all been impact (hail) tested through UL2218. All UL listed products have a Class 4 rating. A Class 4 hail rating indicates a roof panel has survived a 20ft drop of a 2 inch steel ball with no evidence of cracking or tearing of the metal panel. Please note that during hail events, roof panels can still become damaged depending on severity of storm.

What is the best product for high winds?

We have several options to consider. Our Design Span hp and Skyline Roofing hp metal panels are great standing seam (concealed fastener) products to consider. If extremely high wind loads must be designed for, corrugated metal roofing is always an option as well. They can be highly wind resistant, although the exposed fasteners will increase the risk of water penetration vs using a standing seam (concealed fastener) panel.

There are several factors that go into developing the wind load forces for a roof, and wind speed is one of them. Once those wind load forces are determined, then our building code compliance reports ER-0309 and ER-0550 can be used to determine which panel and substrate combinations would work best for your application.

Can ASC Building Products metal roof and wall products be used near the ocean?

Yes! However, like most building materials, there are certain limitations to be aware of. Corrosive environments, like those along the coast, will accelerate the corrosion of any metal. ASC Building Products has warranty limitations regarding coastal installations, primarily those within 1000 feet of the water.

Can a metal roof be installed near the ocean?

Metal can be installed in severe marine environments and coastal environments, but may require an upgraded paint system to provide the required additional corrosion resistance. Severe marine paint systems typically include a high build primer and an additional layer of clear coat over the top to provide additional protection. The needs of these particular systems will depend on the unique environment and the proximity to salt water – ASC Building Products can provide guidance on recommendations for your specific install.

Glossary

The following glossary provides an overview of the common terms used to describe features of metal roofing, metal siding, painted metal finishes, and the metal coating process. If you are having difficulties understanding a term not outlined in this glossary, please submit a query via Ask ASC Building Products.

- A - D

ASTM Standards – The American Society for Testing and Materials is an independent standards organization that regularly publishes testing and performance specifications for a wide variety of industrial products.

Backers – Backers provide the underside of painted metal used in metal roofs and walls with base color, some protection, and a substrate (basis) for adhesives. A backer is typically white or neutral color.

Bonderized – Bonderized refers to the thin layer of Zinc Phosphate on the surface of the sheet that is a weldable product and provides a surface to which paint will readily adhere. This is typically used in rainwater goods such as gutters and flashings for metal roofs.

Camber -The curving or deviation of sheet metal from a straight, vertical plane. Also related to sweep, the curving or deviation of sheet metal from a straight, horizontal plane

Capillary Action – The movement of water through microscopic pores or channels within metal. As water molecules are ‘sticky’ they can flow through narrow spaces often against external forces such as gravity. Usually created when an exposed end of bundled painted steel is in proximity to water due to improper storage, leading to water travelling through the metal, resulting in wet stack corrosion.

Chalking – Chalking is the degradation of the resin system at the surface of the finish on a metal roof or wall, due predominantly to prolonged UV ray exposure. As the resin breaks down, resin particles along with embedded pigment particles lose adhesion and take on a white appearance.

Clear Coat – A clear coat is an optional layer for metal roofs and metal walls applied over the paint top coat designed to add perceived depth to the surface, enhance gloss, or provide an additional layer of protection for extreme environments such as coastal or industrial environments.

Concealed Fastener Roofing – See Standing Seam

Cool Colors – Cool colors refer to a coating for metal roofs which utilize infrared (IR) reflective pigments that have been altered chemically and physically to reflect IR wavelengths while still absorbing the same visible light. Reflecting infrared light reduces the heat buildup in structures, thus reducing building cooling costs.

Corrugated – Corrugated is a common type of metal roof or wall panel design, which incorporates ribs of equal or similar size and shape to create aesthetically pleasing shapes and shadow lines.

Cut-To-Length – Cut-to-length is a manufacturing process in which metal products, typically metal coil, are cut to the exact specifications of an end-user or manufacturer for use in metal roof and wall products.

Delamination – Delamination is the loss of paint film adhesion to the substrate or between the primer and the topcoat. It can be visually apparent in several forms including bubbling, peeling, checking, chipping, cracking, or complete loss of the top coat on a metal roof.

Directional Paint System – Due to the unique shape of the pigments in the paint, common to metallic paints, a directional paint system catches light in a specific way that can vary between batches and orientation. This guidance is given for certain colors to avoid mixing orientation or batches to provide a clean uniform look once installed on a metal roof or wall.

Dissimilar Metals – Refers to metals that are in different positions on the galvanic scale relative to one another. Two dissimilar metals in proximity to one another in a conducive environment can lead to galvanic corrosion, in which one metal corrodes preferentially (and sometimes rapidly) compared to the other metal. This is due to the ‘flow’ of current from one metal to another.

- E - L

Edge Corrosion (field cutting induced) – Corrosion at the exposed, thin, unpainted end of a metal panel. Often created due to field cutting of panels by heat generating devise such as a grinding disk or sawzal (compared to a manufacturers shear or shearing action used on a jobsite to cut material) which leads to an inconsistent, exposed edge which can trap water and spread corrosion more rapidly.

Edge Wave (slitter or roll former induced) – The visible, unintentional waviness, or buckling at the edge of a metal strip due to the forces imparted on the panel during the production or forming process. Often due to improper production or quality control processes.

Electrolysis – Electrolytic Corrosion created by two or more dissimilar metals in contact with each other and an electrolyte containing small amounts of acid. A common example is moisture in a coastal environment. This leads to galvanic corrosion in which one metal will corrode preferentially to the other.

Embossing – Embossing is the process of creating a raised texture to the surface of the metal. Undertaken in a continuous process for metal applications such as metal walls.

Emissivity – Emissivity is the amount of heat a surface can dissipate away from itself. This is expressed as a percentage between 0-100%. Used in the calculation of the Solar Reflectance Index for metal roofs.

Exposed Fastener or Lap Seam Panels – Exposed Fastener or Lap Seam Panels are metal roof and wall panels which are lapped with one over the other, with the fastener then attached from the outside and driven directly through the metal.

Fading – Fading occurs to metal roof and metal wall products when UV rays and substances in the environment attack the pigments in the paint and cause their color to change. Color change is typically assessed based on its variance to the base state when new, represented by Delta E (dE or ΔE).

Film Thickness – Film thickness or dry film thickness (DFT) refers to the thickness of paint film on the strip surface, once the paint has cured. Typical dry film thicknesses for painted steel for metal roof and metal products range from 0.0005″ (0.5 mil) to 0.0015″ (1.5 mil).

Flexographic Roll Printing – Flexographic roll printing is the process Steelscape employs to impart its distinctive colors and designs, such as rustic and aged metallics onto metal for metal roof and wall products.

Galvalume® – See ZINCALUME®

Galvanic (bi-metal) Corrosion – The preferential corrosion of one metal over another, created when two dissimilar metals are in contact with one another in a conducive environment (presence of moisture with acid). Heightened by how dissimilar the metals are on the galvanic scale and how conducive the environment is (e.g. more prominent on the coast than in the desert).

Galvanizing – Galvanizing is the process of coating a thin layer of zinc to steel to improve corrosion resistance. Referred to by Steelscape as TruZinc. For most metal roof and metal wall products that use galvanizing this is applied before the paint layer.

Gauge – Gauge refers to the thickness of metal. A smaller gauge correlates to a thicker metal. For example, 22ga is thicker metal than 29ga. 22ga-29ga are also the most common gauges for metal roof and metal wall building applications. Sometimes spelled as gage.

Gloss and Sheen – Gloss and sheen are two terms used to describe how well a surface reflects visible light. Gloss is measured at a 60° angle from the surface, while sheen is measured at 85°.

Graffiti Resistance – Graffiti resistance, for Steelscape applications, refers to a painted metal wall surface in which aerosol or marker-based graffiti can be removed from the surface.

Inert Catchment – When acidic rainwater, created by certain environmental conditions, creates corrosion in areas downstream of the water catchment surface such as gutters and downpipes. Avoided by ensuring the correct material is selected relative to its environment.

Pressure Mottling – Uneven or irregular gloss visible on painted steel ( often in a splotchy or speckled pattern) due to variation in the pressure applied to the painted surface of the metal when it is stored in coil format. Typically a temporary condition that will dissipate with time.

LEED – Leadership in Energy and Environmental Design (LEED), is a green building rating system developed based on a pre-developed framework for healthy, efficient and environmentally sustainable structures.

Light Reflectance Value (LRV) – Light Reflectance Value measures the amount of visible or usable light that reflects from a surface. LRV is expressed as a percentage from 0 to 100; the higher the number the more visible light that is reflected. Used for both metal roofs and metal walls.

- M - Q

Mechanical Seam – Mechanical seam refers to metal roof products where the seams are mechanically attached together by ‘rolling over’ one seam with another by hand using special tools or with a mechanical seamer. This offers superior weather tightness and product performance in extreme environments.

Metallic Coating – Metallic coating refers to the process of applying additional metal elements, typically Zinc (galvanizing) or Aluminum and Zinc (ZINCALUME® or Galvalume®) to steel to improve corrosion performance of metal roofs and walls.

Mica – Mica is a specially formulated pigment that is added to paint for metal roofs and metal walls to create a sparkling or light-catching effect. This creates the effect of metal flakes in paint but with higher durability.

Oil Canning – Oil canning is a visual phenomenon seen as waviness or distortions in the flat surfaces of metal roofing and metal siding products. This effect is created by a range of different factors including stresses in the base material, improper fastener pressure, misaligned panels, and thermal expansion.

Pre-painted Metal – Pre-painted metal is the continuous process of coating steel rolls, called coils, with paint (also called coil coating). This type of metal is used in metal roofs and walls. The paint that is applied to the metal before it is formed into a finished product by a product manufacturer is called pre-painted metal.

Paint – Paint refers to the film applied to a surface to achieve a desired aesthetic and to protect the material underneath. Metal roof and wall paints typically consists of resins, solvents and pigments. Pigments add color, resins are the binder and add physical and chemical attributes, and solvents dissolve this combination into a liquid form.

Paint System – The paint system consists of a combination of the different painted layers, namely the pretreatment, primer and top coat to create a total finish solution. Paint systems can be modified to achieve different aesthetic or performance characteristics.

Polyester Paint – Polyester Paint is the most economical metal roof paint system and offers the lowest level of UV resistance when compared to SMP (Silicon Modified Polyester) and PVDF (Polyvinylidene fluoride) systems. Versatile and easy to form, their paint structure can be modified to suit a wide range of performance qualities and their flexibility means they can be offered in a variety of color and gloss options.

Pre-treatment – Pre-treatment refers to a coating process applied before painting in which the surface of the metal is cleaned to improve paint adhesion attributes to improve the longevity of painted metal roof and wall products.

PVDF (Polyvinylidene fluoride also known as Fluorocarbon or Kynar 500® and Hylar 5000®) – Polyvinylidene fluoride (PVDF) is the highest performing of the three common metal paint systems. It offers exceptional chemical, chalk, and fade resistance and can resist degradation when exposed to aggressive weather elements such as urban grime, air pollutants, salt, high temperatures and humidity. PVDF can be used on a wide range of preformed shapes, which is why they are often used for high-end architectural and high-profile commercial metal roof and wall projects.

Primers – Primers refers to a coating that prepares the substrate for painting by providing ‘bite’ for adhesion and directly supports topcoat color and flexibility. Primers also provide corrosion resistance for metal roof and wall products.

- R - S

Reverse Impact Test – A reverse impact test is a stress test that is performed to determine if any paint adhesion is lost through a direct impact from the underside of the material. Like the T bend test, this simulates final forming into the finished metal roof and wall product.

Roll Forming – Roll forming is the process used to manufacture the majority of metal roof and wall products. A continuous production process where material is fed through a series of progressive rollers to form it into a finished state. Enables the end panels to be manufactured to desired end user’s length.

Self-Healing Properties – In metallic coatings such as ZINCALUME or galvalume, the galvanic action causes the zinc compounds to automatically build up at cut edges and scratches by an electrolytic reaction when water or moisture is present, slowing the rate of corrosion. This effect is sometimes referred to as “self-healing”. These properties are more pronounced on a factory cut edge with a shea, in which it is smooth and consistent as it essentially folds the Zincalume coating over the exposed raw edge of the base steel. Field cutting (provided its done in a shearing action) can have the same results as a factory cut edge.

Silicon Modified Polyester (SMP) – Silicon Modified Polyester is a paint system with a different resin structure to improve their UV resistance qualities compared to traditional polyester systems. SMPs offer a greater resistance to chalk and fade compared to traditional polyester systems and commonly used in residential metal roof applications.

Slitting – Slitting is a manufacturing process in which the width of a metal coil is trimmed to a desired size, or in which one metal coil is slit to form multiple narrower coils for use in metal roof and wall products.

Snap Seam or Snap Lock Roofing – Snap Seam or Snap Lock Roofing is a type of standing seam metal roof profile which typically have a nailing flange to affix the profile to the roof deck and the seams snap together to form the interlock.

Solar Reflectance (SR) – Solar Reflectance refers to the amount of solar radiation reflected off a metal roof or wall surface. This is expressed as a percentage between 0-100%.

Solar Reflectance Index (SRI) – Solar Reflectance Index is the most common index used to measure the reflectivity effectiveness of a color for a metal roof or wall. The consolidated value calculated from solar reflectance and emissivity with factors such as air flow considered. The higher the value the greater the reflectance. This is expressed as a range so that a standard black surface has an initial SRI of 0, where as a standard white surface has an initial SRI of 100.

Spangle – Spangle is a term to describe the distinctive finished appearance of unpainted ZINCALUME® steel as commonly used in metal roofs and walls.

Stamped Metal Tile, Shake, or Shingles – Stamped Metal Tile, Shake, or Shingles refers to the modular metal roof products manufactured using a stamping process to take on shapes of traditional roofing materials.

Standing Seam Roofing – Standing seam roofing is a common metal roof type for both residential and commercial applications. The seam, is the vertical rib which interlocks between each profile and is raised from the flat base pan of the panel. The fasteners that attach these panels to the structure underneath are covered in the installation process, which is why these profiles are also called concealed fastener roofing profiles. Standing seam reflects one continuous piece from ridge to eave and are available in a variety of widths from 12” up to 20” and beyond.

Striation – Striations refers to the small ridges formed in flat areas of metal surfaces used to reduce the visual impact of oil caning in metal roof and wall products.

Swarf – Swarf refers to the small metallic filings created when metal roofing or siding products are pierced or cut with friction saws, abrasive discs, or drills. If these tiny particles are left on a metal surface, they can corrode and cause rust stains.

- T - Z

T Bend Test – The T Bend Test simulates forming of metal into metal roof and wall products and assesses the flexibility of painted metal. During this test, a bend is formed in the test sample and inspected for any cracking.

Tension Leveling – Tension leveling is an in-line process on both Steelscape metallic coating lines and the Kalama Pickle Line, which induces tension into the strip in excess of the yield strength. Tension leveling results in a flatter product with improved properties for subsequent forming into metal roof and wall products.

Toll Forming – Toll forming is the process of coating or painting metal in which the base metal is provided or owned by the end user.

Top Coat – The top coat refers to the top painted layer of metal which provides metal roofs and wall with the visual color, offers protection from the outside elements, in addition to durability, and weatherability.

TruZinc® – TruZinc® is the terminology used to refer to Steelscape’s computer controlled galvanizing process for metal roof and wall products

Wet Stack Corrosion – The creation of corrosion or blistering to the surface of metal when stored in stacks and bundles. Due to trapped water between metal sheets, the capillary action of water through metal ends or other exposure to moisture due to the improper storage of the metal.

White Rust – The presence of a white, chalky substance on the surface of bare galvanized products. Typically occurs when new galvanized products are exposed to moisture or condensation before the zinc coating has stabilized.

Yield Strength – Yield strength represents the stress at which materials transition from elastic to plastic deformation. Once a material has been loaded past its yield point, it is permanently deformed making it unsuitable for use in metal roof and wall products.

ZINCALUME® (Galvalume®) – ZINCALUME® refers to a metallic coating consisting of 55% Aluminum and 44% Zinc to offer superior corrosion resistance. Coatings using the aluminum-zinc alloy offer a number of advantages to zinc alone. Aluminum is inert and provides a protective rather than sacrificial barrier compared to zinc. This combination is the common industry standard used for metal roof and wall products.