ASC Building Products offers a portfolio of quality metal roofing panels that are engineered and tested to provide long-lasting durability and beauty. We offer a comprehensive range of panel styles in a kaleidoscope of color, ensuring there is an ideal metal roofing panel for any home style. Proven performance and integrity are valuable attributes of your roof and panel supplier. With over 50 years of proven performance, you can rely on ASC Building Products.

Metal Roofing Panels & Sheets

Why ASC Building Products Metal Roof Panels?

- Many Panel Styles – Several metal roof panel and sheet options, including 12”, 16”, and 18” standing seam profiles.

- Performance Options – Offering everything from traditional corrugated metal roof panels to an ASTM high-performance rated Design Span HP standing seam, we have a metal panel solution for your environment.

- Color Versatility – Broad metal panel and sheet color options to suit the style of your home or business.

- Proven Performance – Independently verified to meet building code structural and fire resistance properties for metal roofing panels.

- Efficient Pigments – We offer Cool Roof Rating Council (CRRC) certified metal roofing panel colors that improve building efficiency and lower energy costs.

- Long Warranties – Select residential metal roofing panels come with a limited lifetime finish warranty.

Explore our inventory of metal roofing panels

What Do We Recommend?

Our range of metal roof panels and sheets includes concealed fastener and exposed fastener systems, providing versatile options to suit various building styles and functional requirements.

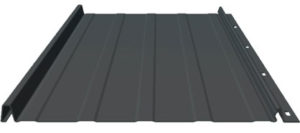

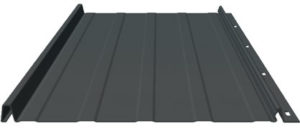

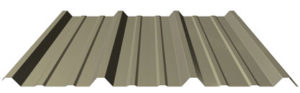

Concealed fastener metal panels like the Design Span® hp and Skyline Roofing® are ideal for those seeking sleek, modern designs and superior roofing performance. These standing seam panels are performance-rated and feature energy-efficient finishes, making them perfect for homeowners looking for a roofing solution to last several decades

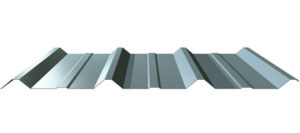

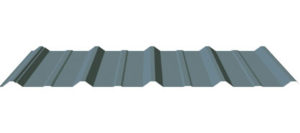

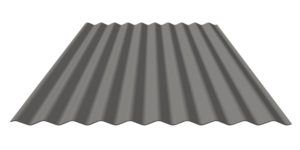

For a more traditional look with a lower price-point, exposed fastener metal panels are a robust choice. Options like Delta Rib™, Nor-Clad®, and the timeless Nu-Wave® Corrugated offer excellent versatility for residential, light commercial, and agricultural applications. These metal panels combine durability with a simpler installation approach, delivering a robust solution at a cost-effective price point.

Energy efficiency is at the forefront of our metal panels and many of our products feature cool pigment technology, reducing heat absorption and helping to lower energy costs. Homeowners can also enjoy peace of mind with limited lifetime finish warranties available on select residential metal panel types. Given how robust our entire color selection is, we recommend selecting a color based on the design vision of your project.

Get Your Journey Started

- Product Guide – Download our Product Guide to browse our complete range of metal roof panels.

- Product Finder – Use the filters to narrow down your search for metal panels to meet your project.

- Visualize – Upload a photo of your home, and our new AI functionality will do the rest, enabling you to visualize metal panels and sheets with ease.

- Design Services – Use our Visualizer’s Design Services to create a 3D model of your project and get a free Eagleview estimation report to help with quoting.

- Get Samples – Request a metal panel or color sample to see how our products will look up close on your project.

- Get in Touch – Ready to get a quote? Reach out to us to find a professional in your area.

Learn why ASC Building Products only manufactures high quality roofing products:

- We independently test the performance of our products –We test our products with third-party agency IAPMO to assess fitness for purpose and longevity.

- We manufacture products to stringent quality standards – Each product is produced on calibrated roll forming equipment, to detailed quality standards with minimal tolerances for deviation.

- We source from quality metal suppliers – Our metal products are sourced from long-standing manufacturers that process and paint the steel here on the West Coast to stringent ASTM testing standards.

- We only use proven paint systems– Our products feature quality paint systems developed by the world’s leading paint suppliers and are independently assessed by the Cool Roof Rating Council.

- We stand behind our products – ASC Building Products offers a limited lifetime warranty for its residential products and stands behind their quality. This is why we’ve been in business for over 50 years.

- We only sell through trusted distributors – To ensure a quality product is delivered to your project, we only sell our products through reputable roofing distributors and wholesalers.

Metal Roofing Panel and Sheet FAQs

What are Metal Roofing Panels and Sheets?

Metal roofing panels and metal roofing sheets are terms commonly used to describe steel and aluminum products used for metal roofing or other building cladding purposes. These products are manufactured in a process called roll-forming. Roll-forming progressively bends flat strips of metal into a range of different product shapes. Forming metal into panels imparts strength, performance, shape, and form to the metal roofing panel. In the roll-forming process, Metal roofing panels are manufactured from a continuous strip of metal, enabling panels to be cut at precise lengths specific to project requirements.

What Are The Main Differences in Metal Roofing Panels?

The two most common types of metal roofing panels are concealed fastened panels and exposed fastener panels. Key differences include:

- Concealed fastener metal roofing panels, such as standing seam roofing, conceal the fasteners once installed. This provides a cleaner look and improved performance by reducing the fastener’s exposure to the elements. Generally, these metal roofing panels are more complex to install and feature narrower panel coverage that contributes to a higher installed cost. The most common application of concealed fastener metal roofing panels is residential and commercial roofing.

- Exposed fastener metal roofing panels are attached to the building by drilling through the panel. This allows for a faster installation process. These panels are generally wider and shipped in nested bundles, which contributes to lower transport costs and installation costs. The most common applications of exposed fastener metal roofing panels are metal buildings and agricultural structures.

Within each of these product groups, metal roofing panels can vary in terms of coverage (width), and the angle, repeat, and depth of panel ribs. Panel rib design can influence panel strength and the prominence of shadow lines.

What Are Important Metal Roofing Panel Product Options?

Outside of the product design, most metal roofing panels will have the following product options:

- Color and paint system – Metal Panels are available in different colors to meet different design criteria and may also be available in different paint systems. Paint systems can vary from good to excellent and influence performance, warranty coverage, and cost.

- Metal thickness –Known as gauge, metal roofing panels are typically offered in two or three different gauges. Metal thickness will directly influence the strength, weight, and cost of the metal panel.

- Other panel-specific options – Metal roofing panels with large flat areas, such as standing seam metal roofing panels, may have options including striations or pencil ribs. These subtle accents can help avoid unintentional waviness associated with light-gauge sheet metal known as oil canning.

How Do I Install Metal Roofing Panels and Sheets?

Each metal roofing panel will have a distinctive installation approach and require care and precision. Installing panels and trims in the correct order, selecting the appropriate fastener placement and pressure, and using correct sealants and closures are all important considerations for a long-lasting metal roofing panel installation. We publish comprehensive metal panel installation guides backed by in-depth YouTube videos to make metal panel installation straightforward.

ASC Building Products offers a range of trims and flashings, color-matched fasteners, and accessory products such as light panels, to ensure there is a complete solution for every metal roofing or siding project. Please consult our detailed metal panel trim and flashing guide for more information.