The Ultimate Mix? Metal and Wood

Design Tips for Mixing Metal and Wood in Building Design

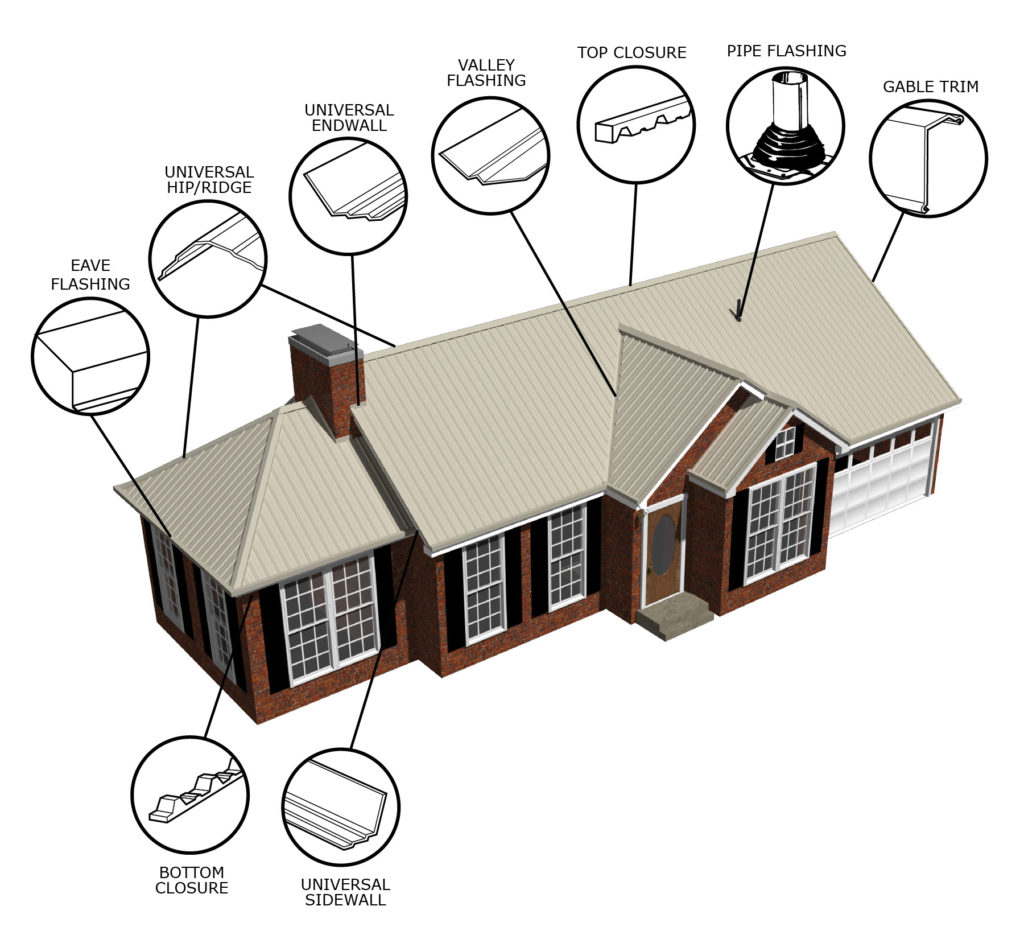

Metal and wood are two striking, yet completely different options for exterior siding materials. One is produced using advanced machinery and narrow tolerances to create a consistent, smooth surface. The other is formed naturally over decades to produce a textured, varied finish. Despite this difference, the two materials can work together in harmony to create truly memorable building designs. Their combination of color, texture, and shadow can transform building surfaces, enhancing curb appeal. Additionally, metal and wood in unison can be used to promote feelings of warmth and nostalgia, to emphasize natural, rustic, and modern design themes, or to add vibrancy to large flat building surfaces.

Stunning mixed metal and wood siding

The application of metal and wood in building design has existed for decades; however, their use together in siding has intensified in interest in recent years. Emerging design trends in metal see the increasing use of standing seam and flush panels as siding profiles, in conjunction with a variety of wood shapes and stains. These metal profiles offer crisp vertical lines in conjunction with smooth flat planes, to offer a restrained yet distinctive wall surface. These lines are often used to contrast horizontally oriented wood shapes. Standing seam profiles have emerged as a popular choice for the additional shadow and texture created by their half, to one-inch seams. The other advantage of these profiles is that the screws are concealed, contributing to the clean uninterrupted lines of the building surface.

Standing seam metal in conjunction with wood siding

Corrugated profiles, particularly those with sinusoidal ribs (a curved shape) continue to be used extensively in mixed material design. The advantage of sinusoidal ribbed profiles is that they can add significant texture to a surface of a building, due to the repeat of the rib design. The rounded edges of these profiles reduce the harshness of the texture and shadow created, enabling the creation of engaging yet restrained siding designs. Although fasteners are exposed on these panel types, corrugated profiles offer a more economical and easier to install solution.

Corrugated metal profile mixed with wood

The use of metal primarily in a vertical orientation not only impacts design aesthetics but can also serve a functional purpose. While most metal panels can be formed up to around 40 ft in length, installing panels is generally easier the shorter the panel. Given the need to accommodate design features such as windows, and to make these interactions weather-resistant, installing flush and standing seam panels in a vertical manner may be both more time effective and provide greater resistance against the elements.

Contrasting material and wood orientation

The most popular wood siding type used in conjunction with metal is lap siding, also known as clapboard or bevel siding, due to its relative ease of installation and the variety of options available. Other styles include tongue and groove siding, which produces a smoother less pounced gap between siding pieces, or drop channel siding, which provides greater shadow and overall siding texture due to the deeper grooves between individual wood panels. Wood shingles and their thicker, more textured cousin, wood shakes offer a different visual aesthetic altogether. The irregular shape of shingles and shakes can be used effectively to add small pockets of varying texture and to create a discernible yet complementary contrast to the smooth lines of metal. Board and batten wood siding is another increasingly popular wood siding type. However, it can produce a visual effect like a standing seam and when used in conjunction with this profile type, may fail to create sufficient visual contrast. For the board, a batten style design, contrasting wood siding to a metal roof is often a more effective way to create visual definition.

Design accent using wood shingles

The real advantage of both material types are the range of color and finish options available. Different wood types not only create different colors, but differing wood grains can further contribute to the overall look created. The variety of stains, paints, or final wood finishing details available, such as charred wood (known as Shou Sugi Ban), further expand the finish options with wood.

A modern home featuring charred wood, shiplap cedar siding and Vintage®

Metal comes in an even broader kaleidoscope of colors, with almost any color of the rainbow available to fulfill a design vision. Like wood, there are several finish innovation options that can further enhance the aesthetic appeal of metal including translucent colors, textures, and printed designs.

Color selection when combining metal and wood must balance several delicate elements. This includes enhancing the integration of the building with its environment, creating a visually cohesive contrast, and accentuating other design themes, colors, or features of the structure. In many applications, the inviting, yet warm colors that can be achieved with wood stains, such as rich ambers and distinctive glows, call for more muted metal colors. As wood elements often serve as design features, versatile metal colors are selected to make design accents stand out and balance the proportions of the rest of the structure.

The rich wood color contrasts with the more subtle gray and silver metal tones.

Wood color options vary based on the stain selected but common tones can include the richer tones of redwood, intermediate tones of pine, or lighter tones common in cypress, cedars, and firs. Grays, bronzes, and charcoals of various shades have emerged as excellent contrasting metal colors. Outside of their balance and environmental integration with wood, these darker shades can also serve to enhance the timelessness of the overall design.

Neutral gray color used to complement wood shakes.

Our Vintage® is a standout color in this space and an underlying reason for its prevalence in modern design. Vintage is a translucent finish that interacts more dynamically with light and it can provide a varying aesthetic that can uplift the color warmth of the surface compared to a solid gray hue. Distressed wood has continued to emerge as a popular material choice; however, these types of woods often lose their rich color as part of the aging process. In these instances, adding additional complimentary warm colors, through prints such as our Natural Rust, can enhance the overall color variety of the structure, provide enhanced visual depth, and reduce unwanted metal sheen.

Our Natural Rust finish on the side of a home.

Vintage®

Natural Rust

While many contractors are skilled at combining natural wood products and metal on a project, there are key considerations to be aware of. The chemicals used in treating lumber can create premature corrosion on metal if water run-off from the wood on to metal occurs in an alkaline environment (such as proximity to the coast). When contemplating a mixed material install, always speak to product manufacturers or your installer for expert guidance.

To learn more about metal colors to complement your next mixed material design, check out our Colors and Finishes, Get Samples or Visualize online using our Product visualizer.

Did you find this article helpful?